Things We Do

We help manufacturers and robotics companies transform visual and sensor data into actionable intelligence by labeling defects, parts, equipment, environments, human interactions, and machine behavior.

Our annotations improve robotic perception, enhance inspection accuracy, and bring

automation to life across industrial workflows.

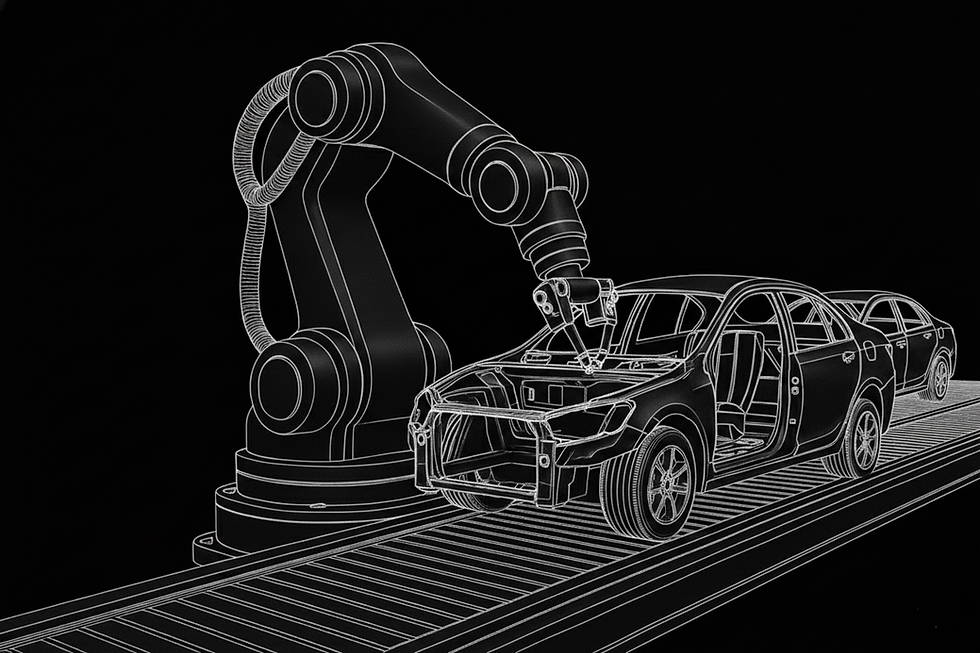

Manufacturing & Robotics

Powering Intelligent Automation Across Manufacturing Floors

From defect detection to robotic vision, Anotag delivers high-accuracy annotations that elevate automation, safety, and production efficiency.

Closer than ever to your next adventure

01

Defect Detection & Quality Control Annotation

We label dents, cracks, scratches, misalignments, missing components, and surface anomalies on parts and products.

This powers machine-vision systems for assembly validation, product quality scoring, and automated inspection.

02

Robotic Navigation & Path

Planning

Anotag annotates factory floors, obstacles, machinery, forklifts, pallet jacks, and human workers.

This helps AMRs and industrial robots navigate safely with accurate map segmentation, object detection, and collision avoidance.

03

Assembly Line

Monitoring

We annotate tools, components, process stages, and worker actions.

These datasets are used to optimize assembly workflows, detect deviations, and ensure consistent SOP compliance.

04

Worker Safety & Behavior

Monitoring

We label PPE compliance (helmets, gloves, vests), unsafe motions, restricted zones, and human-machine interactions.

This strengthens AI systems that prevent injuries and maintain OSHA-level safety standards.

05

Predictive Maintenance & Equipment Condition Analysis

Our team annotates sensor readings, thermal imaging, vibration patterns, and machine states.

This supports AI models that forecast equipment failures and reduce downtime.

06

3D & Depth Sensor Annotation for Industrial Robotics

We work with LiDAR, stereo cameras, depth feeds, and point clouds to annotate industrial environments in 3D.

These datasets enable robotic arms, mobile robots, and automated handling systems to perceive space accurately.

OUR PROCESS

.png)

01

Requirement Analysis & Use-Case Design

We identify your robotic workflows, inspection needs, and manufacturing environments to define the right data strategy.

02

Taxonomy & Schema Development

Custom schemas for parts, defects, equipment types, human roles, and robotic interaction zones.

03

Multi-Modal Annotation Execution

Experts label images, video, LiDAR, thermal, and sensor inputs using manufacturing-trained workflows.

04

Multi-Stage Quality Verification

Human and automated QA ensures > 98% accuracy on defect, part, and positional data.

.png)

05

Iterative Review with Production Teams

We refine guidelines based on model performance, assembly changes, and robotics feedback loops.

06

Secure Delivery & Integration

Datasets delivered in COCO, YOLO, CSV, custom SOP schema, or integrated directly into your robotics/MLOps pipeline.

Why Choose Anotag

Engineered for high-speed, high-accuracy industrial automation.

01

Manufacturing-Trained

Annotation Teams

Skilled in identifying defects, parts, assembly steps, and industrial layouts.

02

.png)

Robotics-Focused Multi-Modal

Support

We handle RGB, thermal, LiDAR, depth, and sensor inputs for robotic perception.

03

Scalable for Global

Factories

Perfect for enterprise operations with multi-site manufacturing and high-volume data.

05

High-Precision QA for

Inspection & Safety

Ensures accuracy for models affecting product quality and worker safety.

06

Experience Across AMRs & Industrial Robotics

Supporting navigation, automation, pick-and-place, and predictive maintenance models.

06

Enterprise-Grade Data

Protection

Built to secure proprietary designs, factory footage, and robotic sensor data.

Security & Trust

Protected with strict protocols designed for industrial environments.

ISO 27001 Aligned

Global-standard security controls to protect factory, robotics, and inspection datasets.

NDA + Restricted-Access

Only authorized teams can access sensitive production data.

SOC 2 Ready Frameworks

Governance built for enterprise manufacturing audits.

Isolated Environments

Dedicated sandboxes to secure high-risk video, blueprint, and equipment data.

Encrypted Data Transfer(AES-256)

All plant footage, thermal images, and sensor outputs are secured end-to-end.

Continuous Security Monitoring

Real-time oversight to safeguard robotics and industrial datasets.

Our Impact in Manufacturing & Robotics

Boosting production intelligence with proven performance gains.

900K+

inspection frames annotated

250K+

depth & point cloud files labeled

98.9%

accuracy on defect classification

30%

faster delivery

Power Your Factory with Intelligent AI Data

Enhance automation, safety, and precision with expertly annotated manufacturing datasets.

From robotic perception to quality control, Anotag delivers data that accelerates smart manufacturing and

next-generation industrial automation.

About the Industry Focus

Manufacturing and robotics are entering a new era where machine vision, automation, and AI-driven decision-making drive productivity, safety, and operational excellence.

Assembly lines, inspection systems, industrial robots, and autonomous mobile robots (AMRs) now rely on precise labeled data to interpret environments, detect anomalies, and interact safely with humans and equipment.

At Anotag, we provide high-quality annotations for industrial inspection, robotic navigation, quality control, predictive maintenance, and factory automation systems. Our teams label images, video streams, depth data, LiDAR, thermal imagery, and sensor inputs used across modern manufacturing environments.

Whether you’re building vision systems for defect detection, training AMRs for autonomous navigation, or enhancing predictive maintenance models, Anotag ensures your datasets are production-grade and industry-ready.

.png)